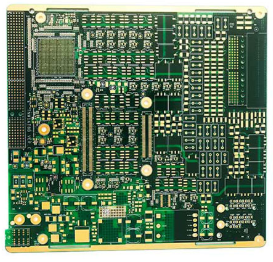

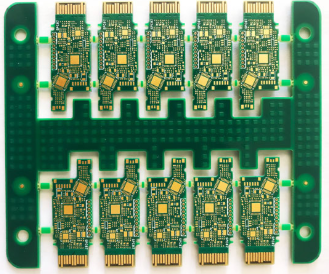

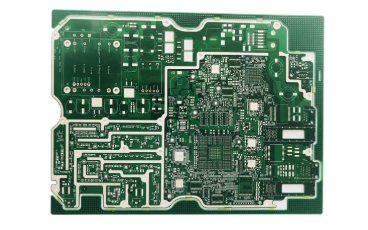

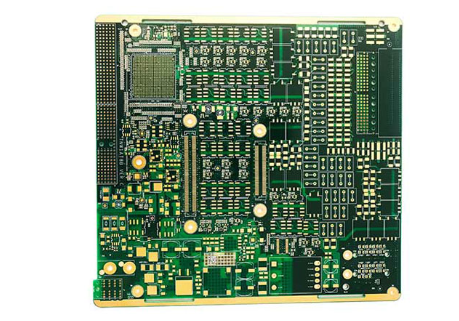

The complete process of chip fabrication includes chip design, wafer fabrication, package fabrication, and testing. The wafer fabrication process is particularly complicated. China is the world's largest importer of e-waste. Every year, 70% of the world's e-waste is shipped to China. The source of e-waste is mostly developed countries such as Europe, America, and Japan. These e-wastes are expensive to handle in their home countries. After arriving in China, transfer to various places for dismantling.

In Huaqiang North, the largest distribution center for electronic components in Asia, many businesses mainly operate renovation and dismantling parts. The source of these disassembled parts and refurbished parts are the dismantlings of e-waste. The low-cost electronic waste is dismantled, and the available electronic components are refurbished and returned to the component market to earn huge price differences, resulting in the proliferation of counterfeit and refurbished electronic components.

So, how do we identify true and false chips when we buy?

1. See if the surface of the chip has polished marks

Any surface of the polished chip will have fine lines or even micro marks on the previous print. Some cover the surface of the chip with a thin coating, which looks a bit shiny and has no plastic texture.

2. See the printing

Most of the current chips are laser-marked or printed on a dedicated chip printer. The writing is clear, unobtrusive, unobtrusive and difficult to erase. Refurbished chips are either "saw-toothed" by the edges of the writing tape and are "saw-toothed", or they are illegible, inconsistent, misplaced, easily erasable or too conspicuous.

In addition, the screen printing process of the current IC manufacturers have long been eliminated, but many chip refurbishment due to cost reasons still use the silkscreen process, which is also one of the judgment basis, the screen printing word will be slightly higher than the chip surface, you can feel the slight unevenness by hand touch Or have a feeling of worry.

However, it should be noted that due to the recent sharp decline in the price of small laser marking machines, more and more refurbished ICs use laser marking, and some new films will use this method to change the wordmark or simply replay to "improve" the chip. The grade, this requires special attention, and the method of distinguishing is more difficult, you need to practice the "eyes of fire."

The main method is to look at the overall coordination, the writing and the background, the new and old degree of the pin does not match, such as the word mark is too new, too clear the possibility of problems, but many small factories, especially some small IC companies in China The chip was born like this, which adds a lot of trouble to the identification, but the judgment of the mainstream big chip is still very meaningful.

In addition, more and more laser marking machines have been used to modify chip markings. Especially in memory and some high-end chips, once the location of laser printing is found to be inconsistent in individual letters and strokes, it can be considered false. goods.

3. Look at the pin

All the tin-plated pins that are as bright as “new” must be refurbished. The majority of the pins of the IC should be the so-called “silver powder feet”. The color is darker but the color is uniform. There should be no traces of oxidation or “flux” on the surface. ", DIP and other plug-in pins should not have traces of wiping, even if there is (repackage will be) scratches should be neat, in the same direction and the metal exposed is smooth and non-oxidized.

4. See the device production date and package factory label

The label of the genuine goods, including the label on the bottom surface of the chip, should be consistent and the production time should be consistent with the product. Although the counterfeit chips have the same frontal label, sometimes the values are unreasonable (such as what the "Geely number" is marked) or the production date does not match the device. If the label on the bottom of the device is confusing, the device is a fake.

5. Measure the thickness of the device and look at the edge of the device

Many original laser-printed refurbished refurbished pieces (mostly power devices) must be ground deeper because of the need to remove the original mark, so the overall thickness of the device will be significantly smaller than the normal size, but not compared or measured with a caliper, the general inexperienced person still It's hard to tell, but there is a general knowledge of breaking the law, that is, looking at the front edge of the device. Because the plastic sealing device must be “released” after injection molding, the edge angle of the device is round (R angle), but the size is not large. It is easy to grind the rounded corner at right angle during the grinding process, so the front edge of the device is right angled. Can be judged as grinding goods.

In addition, there is another method to see if the merchant has a large number of original packaging materials, including the inside and outside of the uniform carton, anti-static plastic bags, etc., the actual identification should be used in multiple ways, there is a problem can be identified The quality of the device.