Here is a Multilayer Flexible PCB Factory talking about introduction to the basic structure of the flexible PCB.

If you want to know about Multilayer PCB Price, feel free to contact us.

When we are using Flexible PCB, do you understand its basic structure and know what it is made of? Let's take a split to let everyone have a simple understanding of the basic structure of the flexible circuit board.

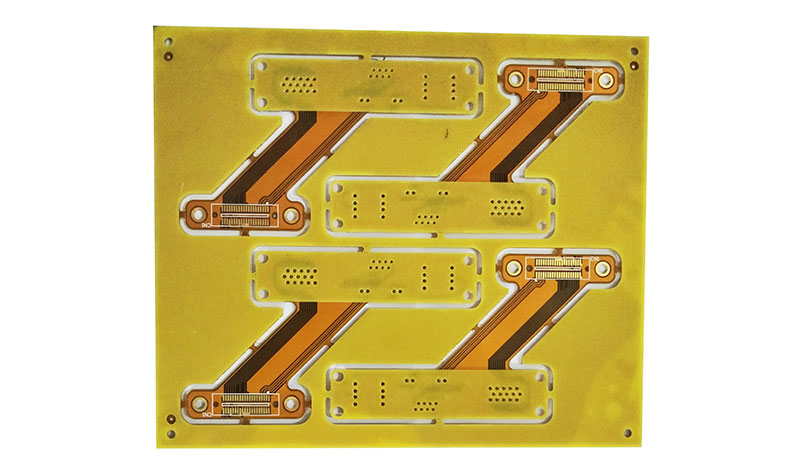

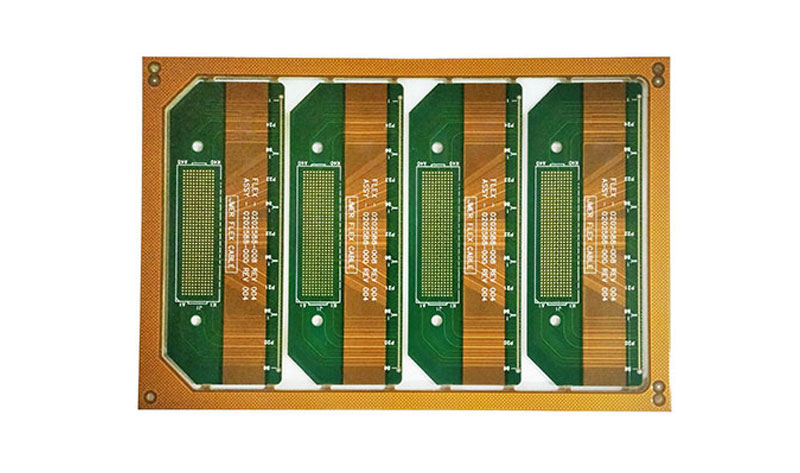

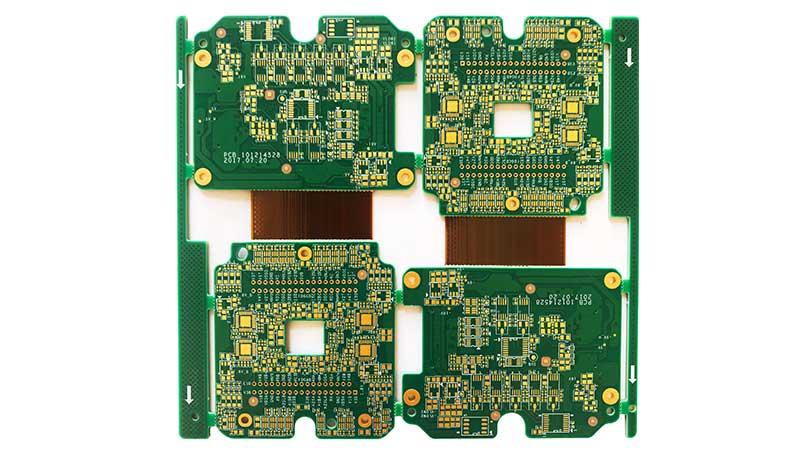

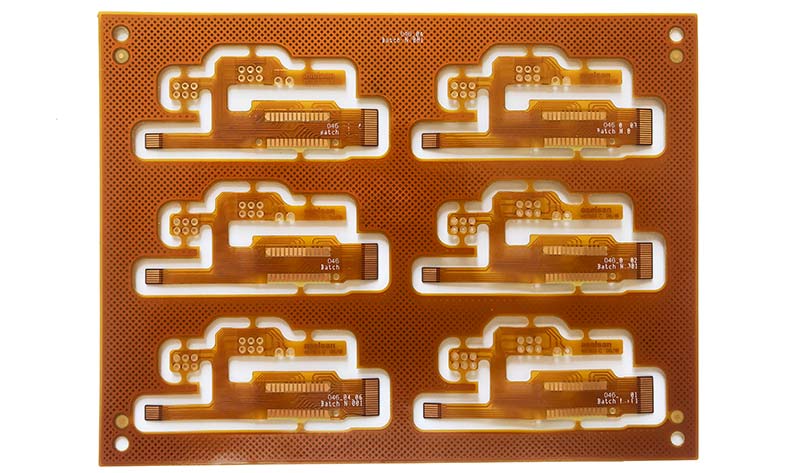

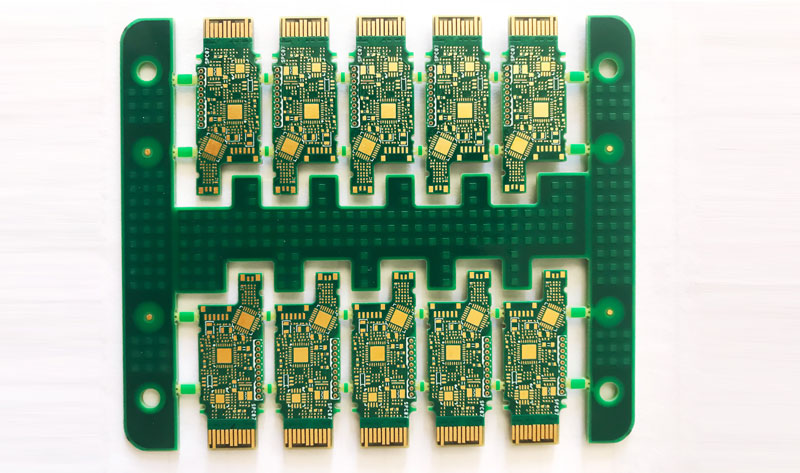

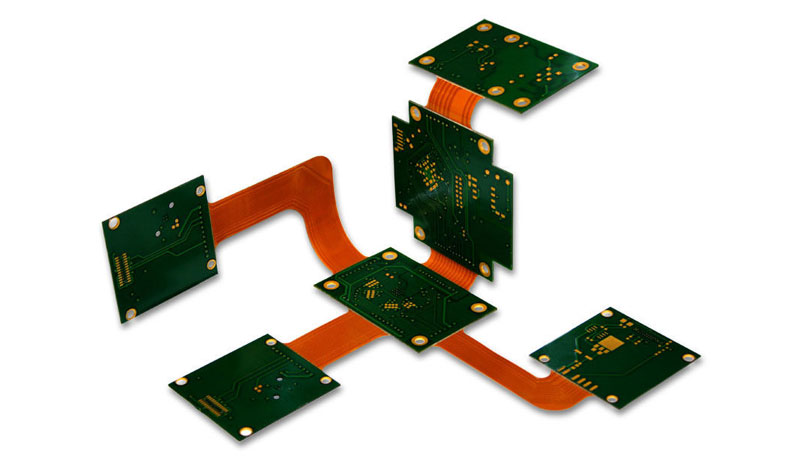

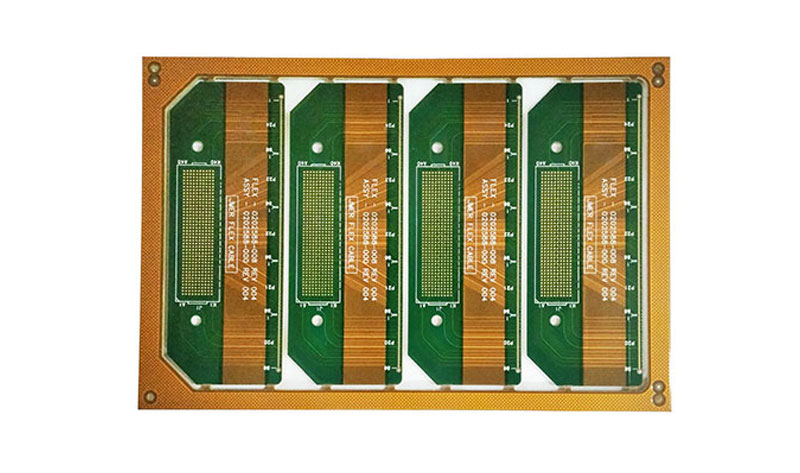

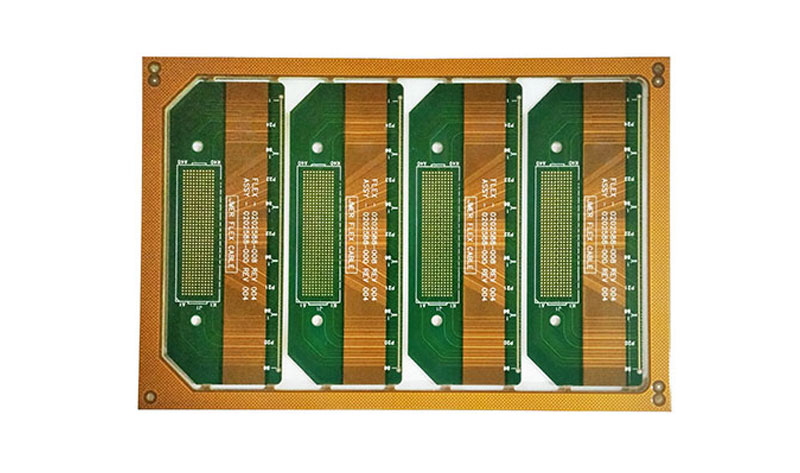

Flexible PCB

Copper foil substrate (Copper Film)

Copper foil: Basically divided into electrolytic copper and rolled copper. Commonly used in thickness are 1oz 1/2oz and 1/3 oz.

Substrate film: common thickness is 1mil and 1/2mil.

Glue (adhesive): thickness depends on customer requirements.

Cover Film

Cover film protection film: for surface insulation. Common thickness is 1mil and 1/2mil.

Glue (adhesive): thickness depends on customer requirements.

Release paper: avoid the adhesive sticking to foreign objects before pressing; easy to work.

Reinforcement plate (PI Stiffener Film)

Reinforcement plate: Reinforces the mechanical strength of the FPC for easy surface mounting. Common thicknesses range from 3 mils to 9 mils.

Glue (adhesive): thickness depends on customer requirements.

Release paper: Avoid adhesive adhering to foreign objects before pressing.

EMI: Electromagnetic shielding film protects the circuit inside the circuit board from external interference (strong electromagnetic area or susceptible area).

Recognizing the basic structure of flexible circuit boards, we have an understanding of the flexible circuit boards. The above is a brief introduction. We welcome a brief understanding of the needs.