Rigid flexible PCB offer incredible flexibility in circuit design, which plays a vital role in the production of complex circuits. Circuitry made up of a combination of rigid and flexible components enables designers to implement complex functions. The rigid flexible PCB design brings a major technological breakthrough. These boards are developed in a 3D environment where developers can fold and distort the PCB to achieve the desired shape. Because conventional boards are inflexible and hard, they are less likely to be used in many sensitive and compact applications such as gadgets, handheld phones, and digital books. So what is the difference between a rigid flexible circuit board and other PCB? The Rigid Flex PCB Board Supplier will tell you next.

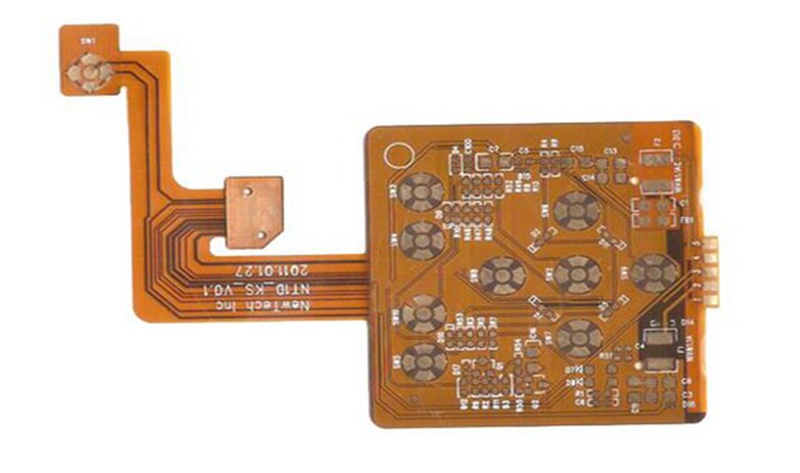

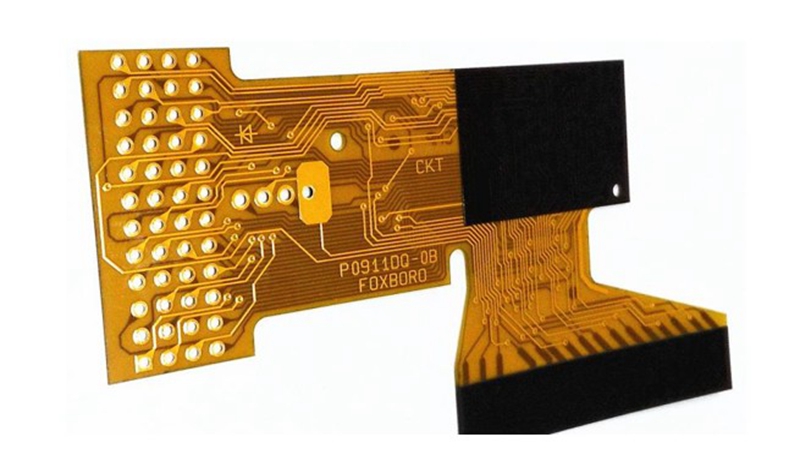

Imagine putting a twisted phone in your pocket and you can even roll and twist like paper, but it still won't break. Sounds amazing? This is one of the technologies being developed by top handset manufacturers. However, the development of such an electronic device without a Flexible PCB is impossible. In addition, sensitive electronic equipment needs to be shockproof, which is impossible without the flexibility of the board. In many applications, a combination of flexibility and rigidity must be used and only rigid plates can achieve the desired function. Rigid flexible PCB are used to ensure the high quality of sensitive hardware. Both rigid and flexible components have specific functions. Rigid boards are used in situations and parts where strength is required, and flexible PCB are used in sensitive parts. The continuous flexible and rigid PCB layer provides unique features that cannot be achieved with a simple PCB.

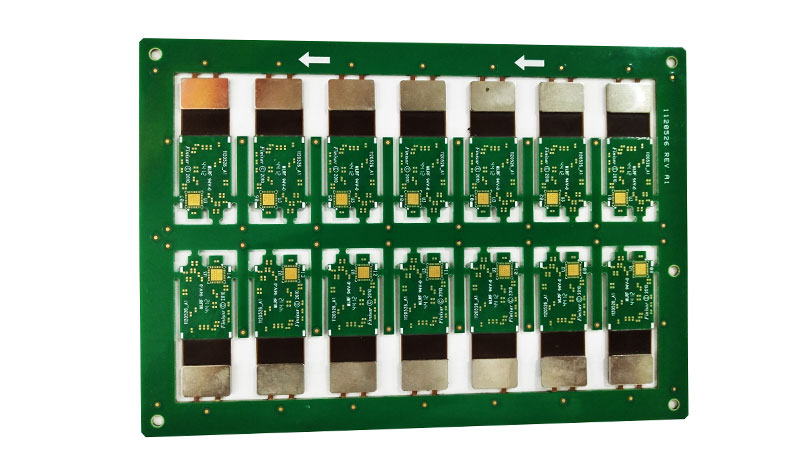

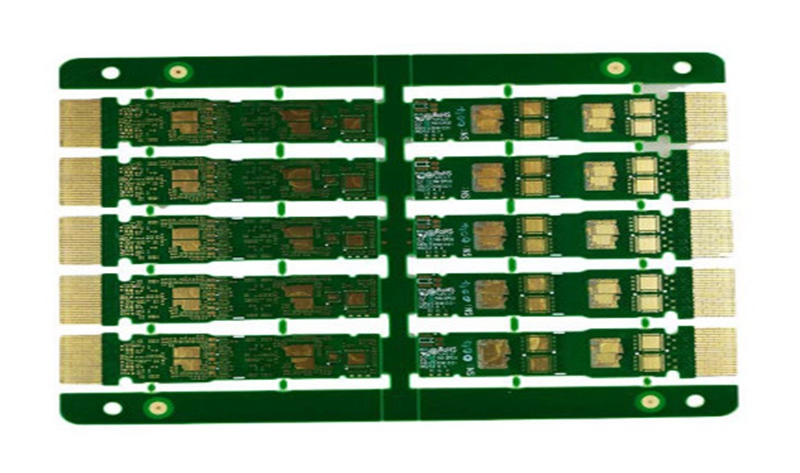

Rigid Flex PCB Board

Rigid Flex PCB Board have been widely used in aerospace and military equipment for the past two decades. Over time, the technology industry is increasingly interested in Rigid Flex PCB. More research is being done to make its boards more reliable and durable while maintaining high quality performance. Since rigid flexible PCB contain flexible and rigid components, the connection boards between these components are developed using interconnect vias. High component density and robust performance are among the distinguishing features expected of Rigid Flex PCB. These features are combined by using a rigid design in the portion where strength is essential, and the panels need to be hard, such as a component landing. Parts such as corners and places that are often subject to vibration are designed for flexibility. In addition, flexible components are suitable where many of the connections need to be skipped by mechanically sensitive areas. The manufacturing process of rigid flexible PCB is completely different from conventional PCB. Special attention must be paid to some sensitive factors in the manufacturing process. For example, copper foil must be etched during the manufacturing process and the flexible polyimide core will shrink. Since shrinkage causes the final dimensions of the circuit to deviate from the design product, dimensional changes must be compensated for during the design process.

Application of rigid flexible PCB:

Rigid flexible PCB are used to make medical devices such as pacemakers. Their low weight and space requirements allow designers to design more reliable products.

Space saving and weight budget, rigid flexible PCB has completely changed the phone and camera. The overall compact design of the latest equipment is mainly due to the reduced size of the circuit.

For similar reasons, rigid flexible PCB are used for military weapons. Because military weapons need to be powerful and effective in performance, rigid flexible PCB are well known for their superior performance. Reducing the weight of the overall product allows the legal plant to design complex weapons. With the integration of rigid flexible PCB in the weapons industry, there will be more progress every day.

They are also used in computer systems and related devices such as hard drives, printers and keyboards. This is mainly because they often require their resistance to vibration, bending, folding, and twisting when designing mechanically robust equipment. Using a cable to route signals in 3d space is not as effective as using a rigid flexible PCB.

In consumer products, Rigid Flex not only maximizes space and weight, but also greatly increases reliability, eliminating many of the needs of welded joints and fragile, fragile wiring that is prone to connection problems. These are just a few examples, but Rigid Flex PCB can be used in almost all advanced electrical applications, including test equipment, tools and automotive.