With the rapid development of mobile phones, electronics, telecommunications and other industries. The printed circuit board industry continues to grow rapidly. At the same time, people are demanding more and more. About PCB quantity, weight, color, material, accuracy, reliability, etc. However, due to competition in the PCB market, PCB materials are also on the rise. Therefore, more and more manufacturers are trying to enhance their core competitiveness. Low prices are often used to monopolize the market.

However, behind these ultra-low costs is a reduction in material costs and production costs. This makes the PCB easy to crack, easy to scratch, unqualified and other comprehensive factors. It will seriously affect the solderability and reliability of the product. So how should we half-quality PCB? The following Rigid PCB manufacturer will come to tell you.

content:

1. Distinguish the quality of the circuit board from the appearance;

2.High-quality PCB board needs to meet the following requirements

Not sure for many electronics engineers and purchasers. In fact, there is no standard method of judgment. But you can make a preliminary judgment from the following points:

The first method is to distinguish them by appearance. The other is to judge the quality specifications from the PCB itself.

1. First, distinguish the quality of the circuit board from the appearance:

The first thing to distinguish is the material used for the plate. Then the ink discolored from the board, the copper was deposited, the surface was treated, and it smelled.

The materials are usually as follows:

The ordinary HB board 22F is the cheapest, and easily deformed and broken, and can only be used as a single panel. The surface of the module is dark yellow with irritating odor, rough copper and thinner color.

Single-sided 94V0 and CEM-1 boards cost more than cardboard but are cheaper than half-glass fiberboard. The component surface is light yellow and is mainly used for industrial boards and switchboards that require fire ratings.

FR4 glass fiber board has high cost but high strength. Basically, most double-sided and multilayer boards use this material, copper can be very accurate, and unit boards are relatively heavy.

Surface treatments include OSP boards, immersion gold boards, hot air solder leveling boards, and other processes. Everything requires that the surface of the PAD is not contaminated. Otherwise it will affect solderability.

In addition, consideration should be given to the size and thickness criteria, and the appearance of the weld. Because this may affect the soldering quality, such as 2 Sided Flexible Circuit Board Material.

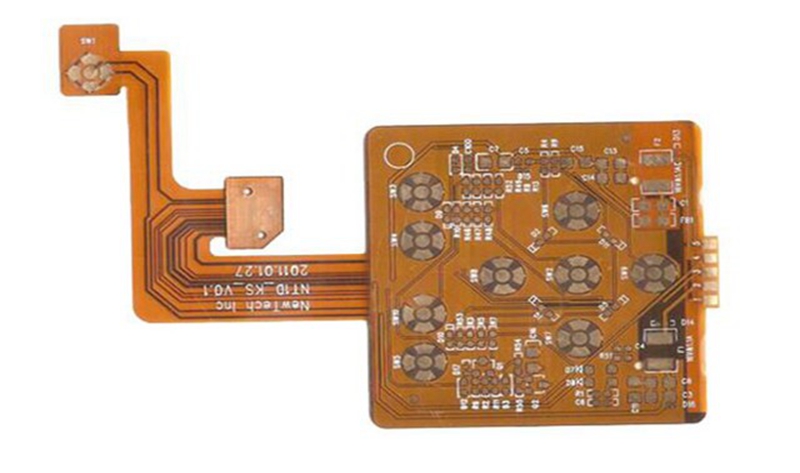

Multilayer Flexible PCB

2. Secondly, high-quality PCB boards need to meet the following requirements:

(1) Meet the electrical connection requirements;

(2) The width, thickness and distance of the line shall meet the requirements to avoid high temperature, breakage or short circuit.

(3) The copper surface should not be easily oxidized. Otherwise it will affect the installation speed and cannot be used for a long time after oxidation.

(4) No other electromagnetic radiation.

(5) The shape is not deformed. All of them are now mechanically installed. And the hole position of the circuit board and the deformation error of the design line should be within the allowable range.

(6) High temperature, high humidity and special environment resistance should also be considered.

(7) The mechanical properties of the surface should meet the installation requirements.

The above is the method for judging the high quality PCB introduced by Multilayer Flexible PCB Manufacturer.

没有评论:

发表评论